- 28/08/2023

- by Health Founders

We sat down with PrintyMed team, another company we’re excited to introduce you from Health Founders batch IV – Accelerator Program 2023!

PrintyMed team focuses on the development of artificial spider silk for different medical applications. Despite the well-known applications of artificial spider silk, their team of scientists, engineers and medical professionals are working together to create material that can be used to create 3D printed living tissue. This unique approach to medicine has the potential to revolutionize the medical field and improve the lives of millions of people.

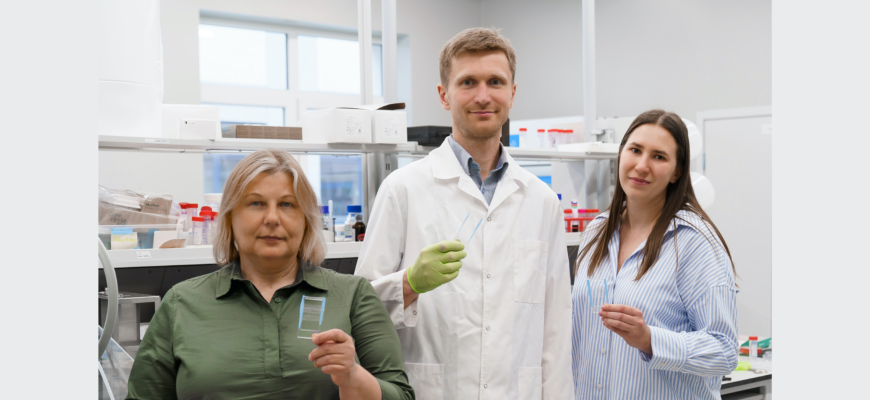

Meet the team: Jekaterina Romanova – CEO, Kristaps Jaudzems – Chief Technical Officer and Sandra Treide – Chief Medical Officer!

…and dive into their interview below as you hear them share about the driving force behind their company and why they are putting their efforts into it.

What is the problem you are solving?

Jekaterina: There is a lack of reliable and biocompatible materials for artificial organ production and we want to solve it.

Sandra: Today for replacing diseased organs or part of them, transplants with a high risk of rejection are being used. Our new material artificial spider silk allows the creation of bioartificial organs, parts, and patches to fix faulty organs.

Kristaps: Despite high medical needs, tissue engineering and regenerative medicine procedures have remained mostly experimental and very expensive. Especially, artificial organs are far from being reliably produced and safely implanted into patients. This is because of several unsolved challenges, which require further optimization. The most important of these is finding appropriate biomaterial scaffolds and (stem) cell preparation procedures for the engineering of specific tissues or organs.

What inspired you to start this company and how did you get started?

Jekaterina: Our start-up is a spin-off of the Latvian Institute of Organic Synthesis. We formed our team during Commercialization Reactor Ignition event. I joined this team because I am crazy about the idea of artificial organ development.

Kristaps: Participation in the workshop “Cutting-edge Entrepreneurship” by Commercialization Reactor inspired me to participate in their organized Ignition Event after we had finished an applied research project on the development of chemically modified artificial spider silk. There, I met several entrepreneurs willing to commercialize our research results, which started our joint journey to establish the company.

Sandra: I am inspired by the great idea of saving lives by creating artificial organs.

Why is now the right time to solve this problem?

Kristaps: Recent advances in biotechnology, bioconjugation, and 3D printing technology have enabled the development of new types of biomaterials for regenerative medicine based on artificial spider silk. The combination of these technologies will allow the printing of artificial organs with excellent mechanical robustness and biocompatibility.

Sandra: Now, because we have the right material and technologies.

Jekaterina: I think that the right time is now because the problem has finally found a solution and there are all the necessary resources available for this solution. Healthcare market needs this solution.

How are you different from your competitors?

Jekaterina: We have a unique chemical modification of the material that allows us to change the material properties and adjust it specifically for each type of cell. Also, we are the only company who have adapted spider silk fiber for 3D printing.

Sandra: In comparison to the transplants, our solution will have fewer rejections and by comparing medical devices, we will provide better comfort. Compared with other artificial spider silks our material is designed for medical needs, it is biocompatible, animal-free, and suitable for bioprinting.

Kristaps: We have a fully water-based technology based on bioconjugation to produce chemically modified artificial spider silk with tailored properties. The technology allows the production of biomaterials with the desired mechanical properties and biodegradability, which can additionally be combined with 3D printing technology.

What are some of the most exciting developments or milestones you’ve achieved so far?

Jekaterina: We have obtained exclusive patent license and developed first heart valve prototype. We’ve had also huge progress on customer development side – we signed the first LOI with a potential client + several in the pipeline, and have attracted first investments.

What is the recipe for a successful team?

Jekaterina: Common big goal and a vision that is really important for each team member, passion and trust.

Kristaps: The perfect combination of the right expertise, mutual trust, and passion for the product to be developed.

Sandra: Setting goals, good communication and respect for each other.

What impact do you hope to have on the healthcare industry in 5 years?

Sandra: Bioartificial organs will reduce about 30% of hospitalization days for patients who need organ transplantation and improve quality of the life for patients after transplantation.

Kristaps: We hope to change the current approach used in tissue engineering and regenerative medicine by providing a new type of biomaterial scaffold, which can be tailored for specific tissues and 3D printed.

To find out more about PrintyMed visit: www.printymed.com